Glow Worm®

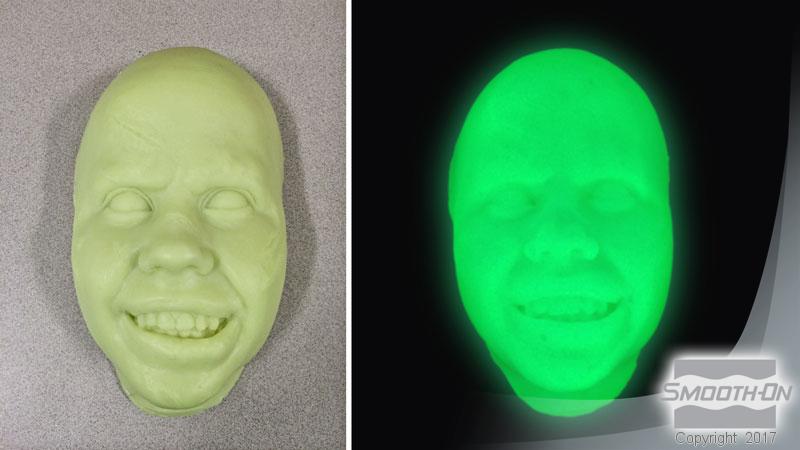

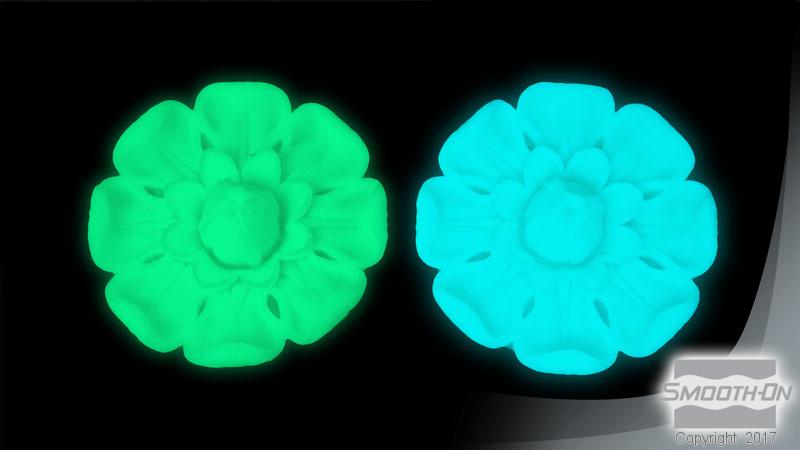

GlowWorm®粉末与其他在暗处发光粉末有何区别?按照说明使用并按照推荐经光线充电后,GlowWorm®粉末制成的浇注件在黑暗中发光时间至少比其他发光粉末长 10倍。

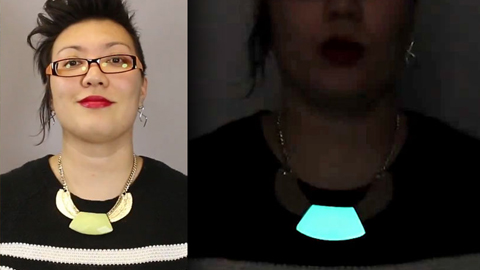

在黑暗中发光的浇注件用于万圣节主题展示、家庭爱好者项目、水族馆、商店展示和更多。材料还用于工业标识、市政安全应用场合和更多。

说明

Directions for Use – Pre-mix all liquid resin, rubber or foam before dispensing. Store and use all materials at or near 73°F/23°C. Glow Worm® powders must be kept dry (see ’Guarding Against Moisture’ section). Use with adequate ventilation. Read and follow directions for material used to mix with Glow Worm® powders. The following example features SmoothCast® 325 (A+B) mixed with Glow Worm® powder. The powder must be thoroughly dispersed into a two component liquid resin or rubber to a uniform consistency.

Recommended Mix Ratio by Volume: 1A + 1B + 1 Part Glow Worm® powder.

By Volume Mixing & Casting Procedure:

- Dispense 1 cup of Smooth-Cast® 325 Part B into a clean mixing container.

- Dispense 1 cup Glow Worm® powder into mixing container.

- Mix thoroughly.

- Dispense 1 cup of Smooth-Cast® 325 Part A into mixing container.

- Mix for 30 seconds until all filler particles are dispersed and pour into rubber mold.

Lower Your Cost Per Casting - Glow Worm Powders are Expensive: Mix small amounts as directed above and brush layers into a mold to coat the mold cavity (known as a face coat or gel coat).

Optional: Combine Smooth-Cast®/Glow Worm® mixture with 1 part Ure-Fil® 11 to increase brushability of gel coat. Follow by backfilling with straight resin or foam.

The glow effect will be the same vs. a solid casting and material cost will be greatly reduced.

Guarding Against Moisture – All powders will absorb atmospheric moisture over time which will react with urethane resins. If you notice a moisture reaction between resin and powder or suspect that your Glow Worm® powder contains moisture, you can remedy by spreading powder evenly over a metal cookie sheet at ¼” (0.6 cm) thickness and bake in oven for 4 hours at 150° F/60° C. Allow to cool before mixing powder with resin. Store powder in a tightly closed container in a cool, dry environment with a desiccant pouch (available at your local hobby/arts and crafts store). Replace used desiccant pouches every other time you open container.

Glow Worm® Powders are up to 50% brighter than the competition.