Rebound™ 25

特征

Rebound™25柔软、有弹性,适合制作深凹陷模型模具。根据模型结构形状,Rebound™25可以作为反向手套模具。Rebound™40较硬,柔韧性低。产品兼容。例如,您可以使用两层Rebound™25,并使用两层Rebound™40进行加固。

特征

优于聚氨酯Brush-On®聚氨酯胶的优势:

- Rebound™不会粘在绝大多数表面上,因此表面准备工作很少。

- 两种液体容易混合在一起

- 在生产浇注树脂和低温熔融金属合金方面表现更好

- 有较长的保存时间

注意:在任何情况下,产品都不适用于含硫的模型粘土。

说明

Store and use material at room temperature (73°F/23°C). Warmer temperatures will drastically reduce working time and cure time. Storing material at warmer temperatures will also reduce the usable shelf life of unused material. These products have a limited shelf life and should be used as soon as possible.

Cure Inhibition - Addition cured silicone rubber may be inhibited by certain contaminants in or on the pattern to be molded resulting in tackiness at the pattern interface or a total lack of cure throughout the mold. Latex, sulfur clays, certain wood surfaces, newly cast polyester, epoxy or urethane rubber my cause inhibition. If compatibility between the rubber and the surface is a concern, a small-scale test is recommended. Apply a small amount of rubber onto a non-critical area of the pattern. Inhibition has occurred if the rubber is gummy or uncured after the recommended cure time has passed. To prevent inhibition, one or more coatings of a clear acrylic lacquer applied to the model surface is usually effective. Allow any sealer to thoroughly dry before applying rubber.

Important: Even with a sealer, Rebound™ will not work with modeling clays containing sulfur. If you are not sure if your clay contains sulfur, do a small compatibility test before using for an important project.

Applying A Release Agent - Although not usually necessary, a release agent will make demolding easier when casting into most surfaces. Ease Release® 200 is a proven release agent for releasing silicone from silicone or other surfaces.Mann Ease Release® products are available from Smooth-On or your Smooth-On distributor.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

MEASURING & MIXING...

Before you begin, pre-mix Part A and Part B separately. After dispensing required amounts of Parts A and B into mixing container (1A:1B by volume or weight), mix thoroughly making sure that you scrape the sides and bottom of the mixing container several times. The rubber should be a uniform color with no streaks.

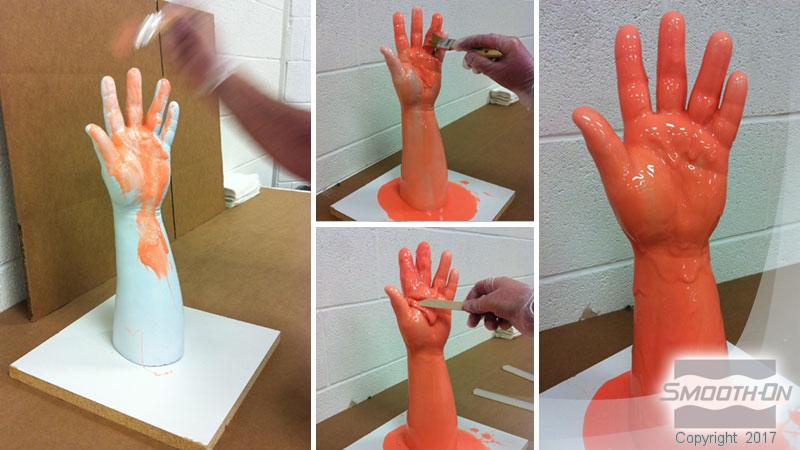

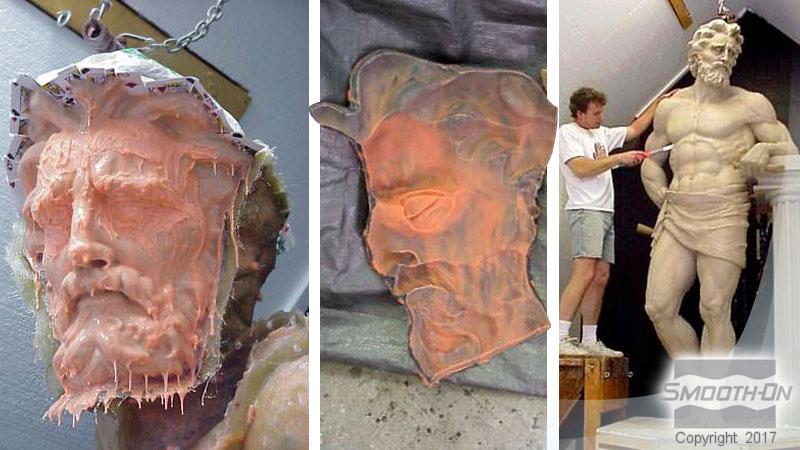

Applying The Rubber - This product must be applied in layers. Mold makers generally find that four thin layers (minimum 3/8” thickness) is suitable for a strong, working mold. Using a stiff brush, the first coat of rubber should be applied in a very thin layer to capture intricate detail. Use dabbing strokes, especially around undercuts, to reduce entrapped air. Subsequent coats will add strength to the mold. Let the first coat dry for 60 minutes at room temperature until it becomes “tacky” before adding the next coat. “Tacky” is defined as sticky to the touch, but does not come off onto your gloved finger. Once “tacky”, you are ready to apply the next layer. Tack-time can be reduced with mild heat (hair dryer or heat gun). Repeat until the necessary mold thickness is achieved.

Coverage: 1 gal. unit=7 sq.ft. (0.65 sq.m) - 5 gal. unit=35 sq.ft. (3.25 sq. m)

Note: Although not necessary, adding a small amount of Silc-Pig® color pigment to every other mix of rubber will help you distinguish one layer from the next. Ensures that you apply a thorough coating each time and help build uniform layers.

Option: Add Thi-Vex® thickener for greater thixotropy—adding a small amount of Thi-Vex® will thicken the rubber for filling deep undercuts and detail. Amount to add? 1% of the total volume of your mix will increase thixotropy substantially.

Option: Add Smooth-On Silicone Thinner to your initial mix to lower the viscosity of your “print coat”.

Apply A Support Shell - Once the mold is fully cured, a rigid support shell (mother mold) is necessary to support the rubber mold during casting. PlastiPaste® II is a trowelable plastic is ideal as a mother mold material.

Curing - Allow the mold to cure at least 6 hours at room temperature (77°F/25°C) before demolding. Do not cure rubber where temperature is less than 65°F /18°C. You can cure the mold faster by applying mild heat (150°F/60°C) for 2 hours.

Using The Mold - When first cast, silicone rubber molds exhibit natural release characteristics. Depending on what is being cast into the mold, mold lubricity may be depleted over time and parts will begin to stick. No release agent is necessary when casting wax or gypsum. Applying a release agent such as Ease Release® 200 (available from Smooth-On) prior to casting polyurethane, polyester and epoxy resins is recommended to prevent mold degradation.

Mold Performance & Storage - The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Casting abrasive materials such as concrete can quickly erode mold detail, while casting non-abrasive materials (wax) will not affect mold detail. Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment.