Mold Max™ XLS™ II

建议使用真空脱气混合材料,以去除包裹的空气。

说明

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Safety – Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Wear vinyl gloves only. Latex gloves will inhibit the cure of the rubber.

Store and use material at room temperature (73°F/23°C). Storing material at warmer temperatures will also reduce the usable shelf life of unused material. These products have a limited shelf life and should be used as soon as possible.

Applying a Sealer / Release Agent - Mold Max™ rubber may be inhibited by sulfur based clays resulting in tackiness at the pattern interface or a total lack of cure throughout the mold. If compatibility between the rubber and the surface is a concern, a small-scale test is recommended. Apply a small amount of rubber onto a non-critical area of the pattern. Inhibition has occurred if the rubber is uncured after the recommended cure time has passed. To prevent inhibition, a “barrier coat” of clear acrylic lacquer sprayed directly onto the pattern is usually effective. Allow to thoroughly dry. Although not usually necessary, a release agent will make demolding easier when pouring into or over most surfaces. Ease Release™ 200 is a proven release agent for making molds with silicone rubber and for releasing new silicone from cured silicone. Mann Ease Release™ products are available from Smooth-On or your Smooth-On distributor.

Measuring & Mixing - Before you begin, pre-mix Part B thoroughly to re-disperse pigments that may have settled. Using a gram scale, dispense required amounts of parts A and B into a mixing container and mix for 3 minutes. Scrape the sides and bottom of the container several times. After mixing parts A and B, vacuum degassing is recommended to eliminate any entrapped air in pourable Mold Max™ rubber. Vacuum material for 2-3 minutes (29 inches of mercury), making sure that you leave enough room in container for product expansion.

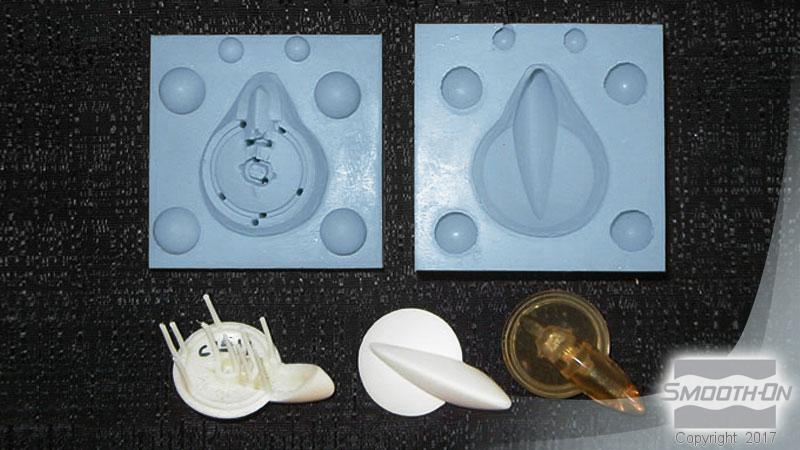

Pouring / Curing / Post Curing - For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. A uniform flow will help minimize entrapped air. The liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface. Allow the mold to cure overnight (at least 16 hrs) at room temperature (73°F/23°C) before demolding. Post curing the mold an additional 4 hours at 150°F (65°C) will eliminate any residual moisture and alcohol that is a by-product of the condensation reaction that can inhibit the cure of some urethane resins and rubbers. Allow mold to cool to room temperature before using. Do not cure rubber where temperature is less than 65°F/18°C.

Thickening Mold Max™ XLS™ II For Brush-on Application - THI-VEX™ is made especially for thickening Smooth-On’s Mold Max™ XLS™ II silicone for vertical surface application (making brush-on molds). Different viscosities can be attained by varying the amount of THI-VEX™. Apply a thin coat of rubber. Wait for rubber to become “tacky” before applying next coat. Final mold thickness should be at least 3/8” (1 cm). Allow rubber to cure overnight before applying support shell. See the THI-VEX™ technical bulletin (available from Smooth-On or your Smooth-On distributor) for full details.

Accelerating Mold Max™ XLS™ II - Accel-T™ Silicone Rubber Accelerator will accelerate the cure time of Mold Max™ XLS™ II silicone rubber. Note: working time is reduced in proportion to the amount of Accel-T™ added. See the technical bulletin for Accel-T™ (available from Smooth-On or your Smooth-On distributor) for exact mix ratios and cure times. Using this accelerator will result in a shorter library life of the mold.

Thinning Mold Max™ XLS™ II - Silicone Thinner™ is a non-reactive silicone fluid that will lower the mixed viscosity of tin cure (condensation) or platinum cure (addition) silicone rubbers.

Silicone Thinner™ offers the following advantages: [1] A lower mixed viscosity (A+B) means that the rubber will de-air faster when vacuuming; [2] Mixed rubber (A+B) will flow better over intricate model detail; [3] Silicone Thinner™ will lower the ultimate shore hardness (durometer) of cured silicone rubber; [4] Pot life (working time) is increased in proportion to the amount of Silicone Thinner™ used. A disadvantage is that ultimate tear and tensile are reduced in proportion to the amount of Silicone thinner added, however knotty tear properties of the Mold Max™ Series rubbers are unaffected. It is not recommended to exceed 10% by weight of total system (A+B). See the Silicone Thinner™ technical bulletin(available from Smooth-On or your Smooth-On distributor) for full details.

Mold Performance & Storage - The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Casting abrasive materials such as concrete can quickly erode mold detail, while casting non-abrasive materials (wax) will not affect mold detail. Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment.