TASK™ 18

说明

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal™ Mold Release or Mann’s Ease Release™ 200 available from Smooth-On or your Smooth-On distributor). A liberal coat of release agent should be applied onto all surfaces that will contact the plastic.

IMPORTANT: To ensure thorough coverage, apply release and brush with a soft brush over all surfaces. Follow with a light mist coating and let the release agent dry for 30 minutes.

Smooth-On silicone rubber molds usually do not require a release agent unless casting silicone into the mold. Applying a release agent will prolong the life of the mold.

Measuring - The proper mixing ratio is 26 Parts A to 100 Parts B by weight. You must use an accurate scale (gram scale or triple beam balance scale) to weigh these components properly. Dispense the required amount of Part A into a mixing container. Weigh out the appropriate amount of Part B and combine with Part A.

Mixing - Materials should be stored and used in a warm environment (73° F / 23° C). Shake or stir Part A & Part B before using. Add Part A to Part B and mix thoroughly. Stir slowly and deliberately making sure that you scrape the sides and bottom of the mixing container several times. Be careful not to splash low viscosity material out of container.

If tinting or pigmenting TASK™ 18, add the tint or pigment dispersion to Part B and mix thoroughly before adding Part. A.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

Pouring - If casting TASK™ 18 into a rubber mold, pour mixture in a single spot at the lowest point of the mold. If encapsulating an object, do not pour the mixture directly over the object. Let the mixture seek its level. A uniform flow will help minimize entrapped air.

For Best Results . . . Best results are obtained using a pressure casting technique. After pouring the mixed compound, the entire casting assembly (mold, dam structure, etc.) is placed in a pressure chamber and subjected to 60 PSI (4.2 kg/ cm2) air pressure for 16 hours.

Curing - Important: Use this product with at least room size ventilation or in proximity to a forced outlet air vent and do not inhale/breath fumes. Fumes, which may be visible with a significant mass concentration, will quickly dissipate with adequate ventilation. Castings with significant mass may be hot to the touch and irritate skin immediately following cure. Let casting cool to room temperature before handling.

Demold time of the finished casting depends on mass and mold configuration. Low mass or thin-walled castings will take longer to cure than castings with higher mass concentration.

If making rotational or hollow castings, backfilling with a rigid foam (Foam-iT! 5 or other) will provide lightweight reinforcement. Foam backfilling is recommended if castings will be subjected to temperatures above 85°F / 30°C.

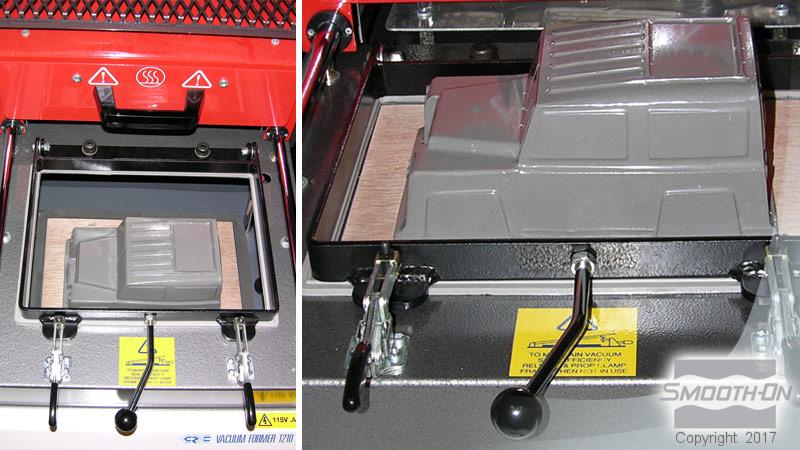

Post Curing - Castings will reach “full cure” faster and achieve maximum physical properties and higher heat resistance if TASK™18 is post cured. Post curing is necessary if using TASK™18 as a vacuum forming mold/die. Post curing is recommended if castings are thin or low mass concentration. Castings should be post cured in a mold or support structure.

Post Curing Schedule - Allow the material to cure for 16 hours at room temperature, followed by 2 hours at 140°F/ 60°C , then 2 hours at 212°F/ 100°C. Allow casting or part to cool to room temperature before handling.