Soma Foama® 25

说明

Cure Inhibition - Addition cured silicones may be inhibited by certain contaminants such as sulfur, polyesters, certain wood surfaces, epoxies, urethane rubber and tin catalyzed silicones resulting in tackiness at the pattern interface or a total lack of cure throughout the mold. If compatibility between the rubber and the surface is a concern, a small-scale test is recommended. Apply a small amount of foam onto a non-critical area of the pattern. Inhibition has occurred if the matrerial is gummy or uncured after the recommended cure time has passed. This product will not cure against tin-based silicone rubbers.

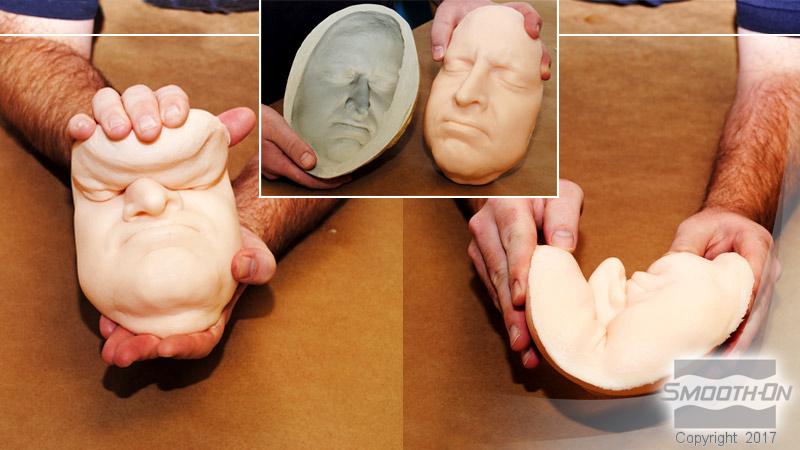

Applying A Release Agent - Soma Foama® will stick to some surfaces and a release agent may be necessary to facilitate demolding. When casting Soma Foama® into or over other platinum silicones, apply Ease Release® 200 prior to applying foam. IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces. Let the release agent dry for 15 minutes.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Mixing - Mixing can be done by hand or using a drill and a mixer attachment, such as a “squirrel” mixer. After dispensing required amounts of Parts A and B into mixing container, mix thoroughly for 30 seconds. Stir quickly and deliberately, making sure you scrape the sides and bottom of the mixing container several times. Be careful not to splash material out of the container. Remember, foam cures quickly. Do not delay between mixing and pouring. Elevated temperatures will result in a reduced pot life and cure time.

Warning - A small amount of Hydrogen gas is released as part of the A:B reaction. Use only with adequate ventilation and do not breathe fumes. Also do not smoke or have other ignition sources in proximity to this product during mixing and pouring.

Pouring - For best results, pour your mixture in a single spot at the lowest point of the containment field and let the mixture seek its own level.

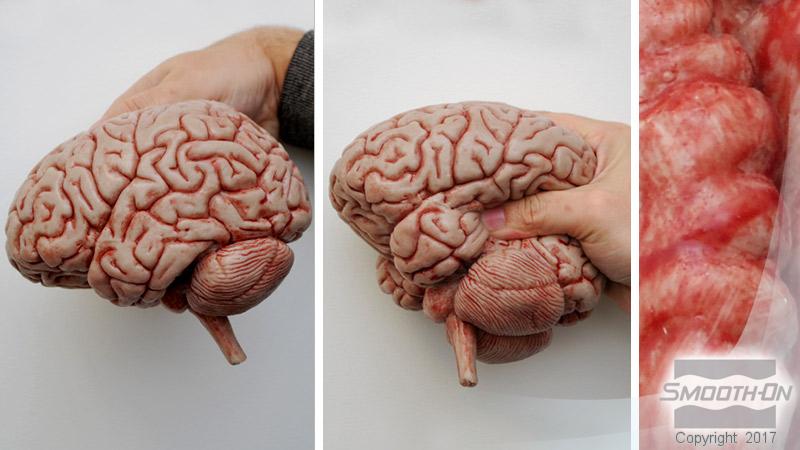

Handling Strength is 20 minutes with full cure in 1 hour at room temperature. Foam color will darken over time. Adding Silc-Pig® silicone pigments will help stabilize color of cured foam. To adhere Soma Foama® to other platinum silicones, best adhesion is realized when poured against newly cured platinum silicone rubber.

Results May Vary: This material is subject to variables such as high or low environmental temperatures. A small test to determine how material performs for your application is recommended. Improve Surface Finish and Minimize Voids With Back Pressure Use a board that will completely cover the mold opening. Using a ¾” (2 cm) drill bit, drill 3 holes in the board spaced a few inches / cm apart. Make sure that, when the board is placed over the mold opening, the holes are over the mold cavity and rising foam will be able to make it through. Apply Ease Release® 200 thoroughly to both sides of the board and into the drilled holes. Mix and pour foam into mold cavity and place board over mold opening. Hold board firmly in place. As foam rises in the mold cavity, some foam will grow out of the drilled holes. After the foam stops growing, you can let go of the board. Do not demold for at least 20 minutes.

Demold - After 20 minutes, cut excess material that came through holes. Gently remove board and casting.