Smooth-Cast® 57D

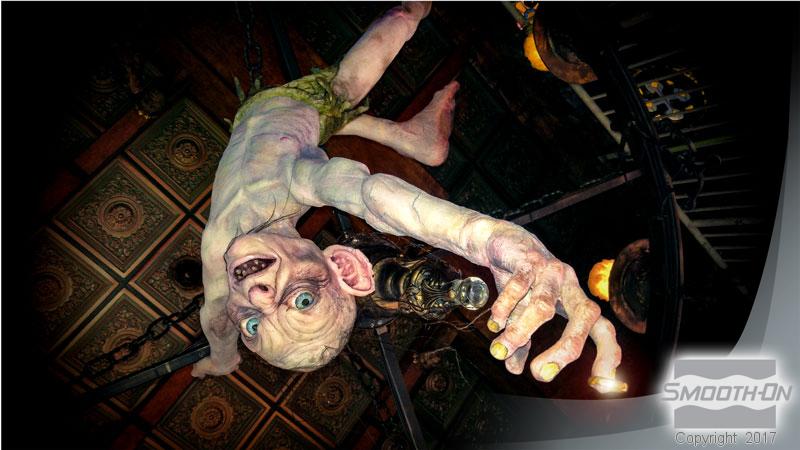

用于旋转浇注 - 倒入合适的橡胶模具中,旋转模具,树脂混合物逐渐涂覆模具腔体的内部。获得足够的壁厚后,固化的空心浇注件具有半刚性和高度抗冲击性。

用作浇注树脂 - Smooth-Cast®57D也可用作浇注树脂,用于制做坚固耐用的半刚性浇注件。

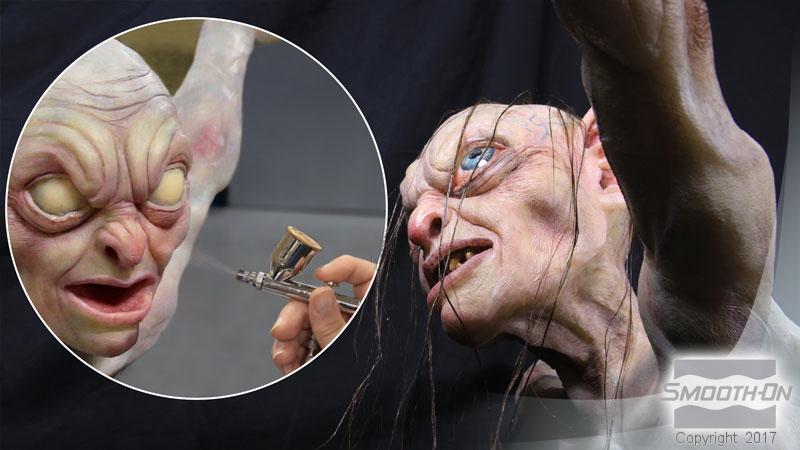

体积混合比例为1A:1B。操作时间为3分钟,脱模时间为30分钟,24小时后达到完全固化性能。颜色为半透明白色,容易使用SO-Strong®、UVO®或Ignite®颜色进行着色。固化后的树脂也很容易用丙烯酸涂料或UreCoat®柔性涂层材料进行喷涂,用于需要耐用表面的应用场合。

说明

Materials should be stored and used in a warm environment (73°F / 23°C). This material has a limited shelf life and should be used as soon as possible. Mixing should be done in a well-ventilated area. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. All liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal, glass or plastic. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Applying A Release Agent

A release agent is necessary to facilitate demolding when casting into or over many surfaces. Use a release agent made specifically for mold making and casting such as Mann’s Ease Release® 200 available from Smooth-On. A liberal coat of release agent should be applied onto all surfaces that will contact the plastic.

~IMPORTANT: To ensure thorough coverage, apply release and brush with a soft brush over all surfaces. Follow with a light mist coating and let the release agent dry for 30 minutes.

Smooth-On silicone rubber molds usually do not require a release agent unless casting silicone into the mold. Applying a release agent will prolong the life of the mold.

Mixing

Pre-Mix PART-A and PART-B Thoroughly Before You Begin. After pre-mixing both parts, dispense required amounts of Parts A and B into mixing container and mix thoroughly. Stir for at least 30 seconds, making sure that you scrape the sides and bottom of the mixing container several times.

Curing

Important: Use this product with at least room size ventilation or in proximity to a forced outlet air vent and do not inhale/breath fumes. Fumes, which may be visible with a significant mass concentration, will quickly dissipate with adequate ventilation. Castings with significant mass may be hot to the touch and irritate skin immediately following cure. Let casting cool to room temperature before handling.

Demold time of the finished casting depends on mass and mold configuration. Low mass or thin-walled castings will take longer to cure than castings with higher mass concentration.

If making rotational or hollow castings, backfilling with a rigid foam (Foam-iT! 5 or other) will provide lightweight reinforcement. Foam backfilling is recommended if castings will be subjected to temperatures above 85°F / 30°C.

Performance

Cured castings are semi-rigid and impact resistant. They resist moisture, mild heat, solvents (intermittent contact) and can be primed/painted or bonded to other surfaces (any release agent must be removed) using Urebond or similar flexible adhesive. If machining material, wear breathing protection. Unpainted castings may discolor in proportion to duration and intensity of exposure to UV light.

If suitability of any Smooth-On material is in question for your application, a small scale test is recommended before using for an important project.