PMC®-770

PMC®-770邵氏硬度为Shore 70A,用于各种工业和浇注应用中工业液体聚氨酯产品补充产品(如PMC®-780和PMC®-790)。按重量将A和B两组分混合,浇注容易,室温下固化成坚固的邵氏硬度为Shore 70A的橡胶,具有出色的性能和尺寸稳定性。

说明

Some Materials Must Be Sealed - To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. SuperSeal® or One Step® (available from Smooth-On) is a fast drying sealer suitable for sealing porous surfaces without interfering with surface detail. You can also use Sonite® Wax. A high quality Shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based).

In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent.

Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent.

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal® Mold Release available from Smooth-On). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

IMPORTANT: Shelf life of product is drastically reduced after opening. Immediately replacing the lids on containers after dispensing product will prolong the shelf life of the unused product. XTEND-IT® Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic.

IMPORTANT: Pre Mix the Part B before using. After dispensing the required amounts of Parts A and B into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times.

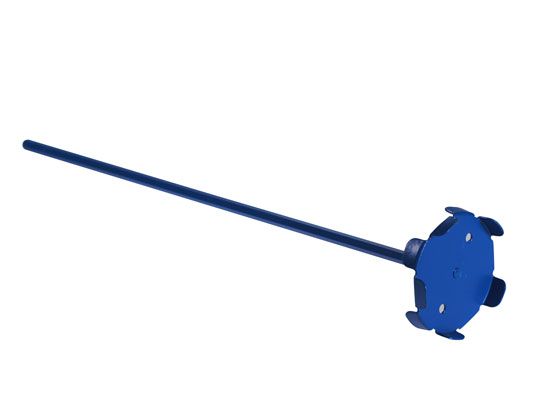

If Mixing Large Quantities (24 lbs./11 kgs. or more) at one time, we suggest using a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again.

Although this product is formulated to minimize air bubbles in the cured rubber, vacuum degassing will further reduce entrapped air. A pressure casting technique using a pressure chamber can yield totally bubble free castings. Contact SmoothOn or your distributor for further information about vacuum degassing or pressure casting.

Pouring - For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. A uniform flow will help minimize entrapped air. The liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface.

Curing - Allow the mold to cure (at least 16 hours) at room temperature (73°F/23°C) before demolding. Do not cure rubber in temperatures less than 65°F/18°C. Cure time can be reduced with mild heat or by adding Smooth-On “Kick-It®” Cure Accelerator.

Post Curing - After rubber has cured at room temperature, heating the rubber to 150°F (65°C) for 4 to 8 hours will increase physical properties and performance.

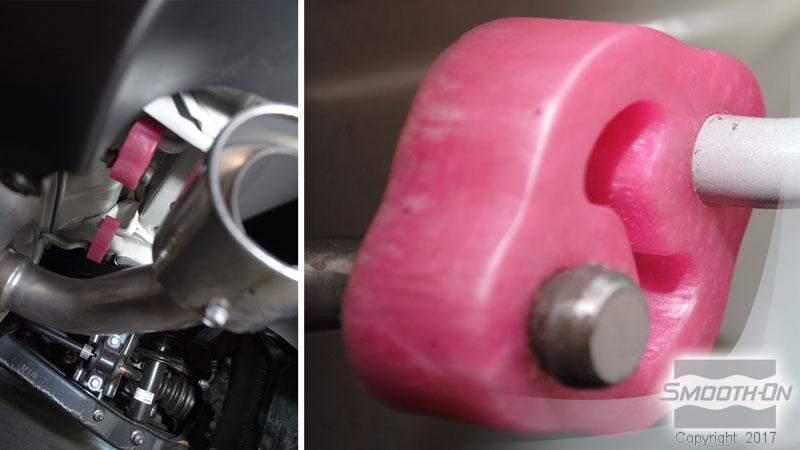

Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. Smooth-On liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor). Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. In & Out® II Water Based Release Concentrate (available from Smooth-On) is recommended for releasing abrasive materials like concrete.

Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored. The physical life of the rubber depends on how you use it. Contact Smooth-On directly with questions about this material relative to your application.