如何复制火器和枪

概述

Overview

Smooth-On mold rubbers and casting resins can be used to recreate historic and modern firearms. This tutorial will show you the different methods of mold making and casting to recreate these pieces.

Who Uses These Materials?

Firearms Manufacturers

Holster Makers

Law Enforcement

Gun Stock Fabricators

Prop Makers

Museums

Government Agencies

Target Manufacturers

Step 1: TASK® 16 Prop Pistol

TASK® 16 liquid urethane plastic prop pistol cast in Mold Star® 16 silicone rubber mold.

Step 2: TASK® 8 Rifle Casting

TASK® 8 casting of a Nicolas Hawk Kentucky rifle.

Step 3: Resin Pistol Grips

Colt 45 pistol grips cast in various urethane resin with SO-Strong® tints, Metal, and CastMagic® powders.

Step 4: Applying Rebound™ 25 Silicone

Initial coat of Rebound™ 25 silicone mold rubber is brushed over original 1840 longrifle.

Step 5: TASK® Assault Rifle

TASK® 16 prop casting of a MP-5 assault rifle.

Step 6: Pour On Mold of Powder Horn

Mold Star® 15 silicone rubber poured over an early powder horn.

Step 7: Metal Cold Cast Long Rifle

Brass and Nickel Silver metal powders used in Metal Cold Cast technique for longrifle.

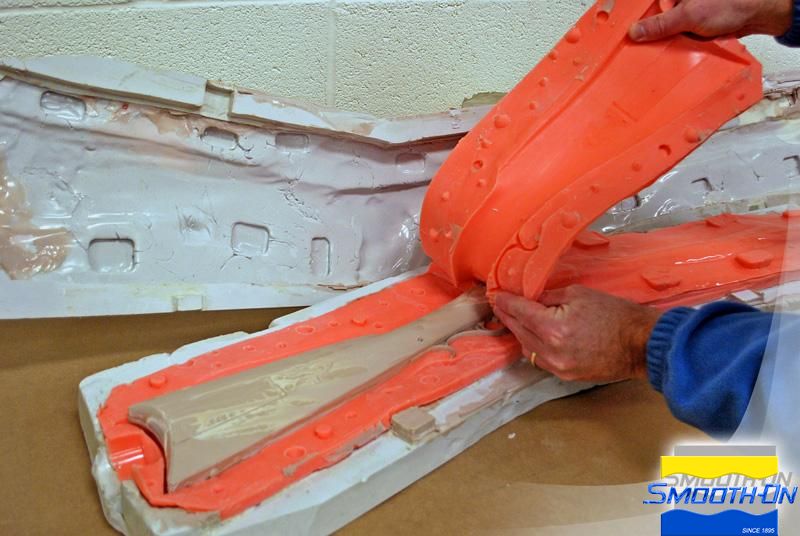

Step 8: Smooth Cast® 320 Long Rifle

Demold of Smooth-Cast® 320 resin casting of longrifle from a Rebound® 25 mold.

Step 9: Finishing Smooth Cast® Resin Castings

Final touches of paint complete exact reproduction of mid 19th century longrifle cast using Smooth-Cast® 320.

Step 10: Painting Reproduction Powder Horn

1792 powder horn cast in SmoothCast® 65D and painted to match original.

Step 11: Finished Duplicate Patch Knife

Circa 1820 patch knife cast with Smooth-Cast® 65D semi-rigid urethane resin.

Step 12: Mold Max™ Flare Gun Mold

Webley flare gun mold created from Mold Max™ 30 silicone.

文件下载 ›